The Best Guide To Plastic Injection Molding

Wiki Article

Plastic Injection Molding Things To Know Before You Buy

Table of ContentsGetting The Plastic Injection Molding To WorkThe Greatest Guide To Plastic Injection MoldingPlastic Injection Molding Things To Know Before You Get ThisPlastic Injection Molding Things To Know Before You Buy

If you wish to check out additionally, the overview covers sorts of mould tools, along with special finishing procedures such as colours & plating. Words that are underlined can be located in the glossary in the appendix ... Component I: Moulding: The Fundamentals The Advantages of Shot Moulding Plastic injection moulding is a really accurate procedure that provides numerous advantages over various other plastic processing approaches.

Precision is excellent for extremely intricate components. Compared to various other techniques, moulding enables you to incorporate more attributes at very little tolerances. Have an appearance at the picture to the. You can hold this moulding in the palm of your hand and it has employers, ribs, metal inserts, side cores as well as openings, made with a sliding closed off feature in the mould tool.

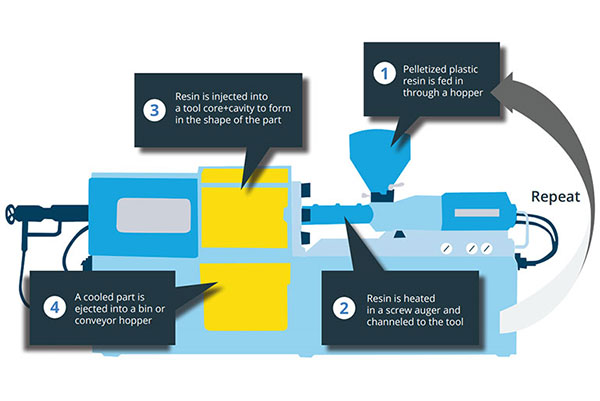

The molten plastic cools down & sets into the shape inside the mould device, which after that open up to allow the mouldings to be ejected or gotten rid of for assessment, distribution or secondary operations. Stage 1Material granules from the hopper feed right into the warmed barrel & revolving screw. Product thawed by heat, friction & shear force is forced with a check valve to the front by the turning screw ... Component III - Past the Essential - Tooling Options Production in China can conserve you a great deal of price, but it can come with problems such as delivery delays, miscommunications, inferior quality as well as the paperwork bordering importation. Using a UK moulder with existing connections to China can eliminate the risk and still result in cost-saving ... Dental caries - The part of an injection mould device that offers the plastic item its form, that does the real moulding of the plastic. Additionally see mould device chapter on pages 5 and 6 for all terms associated with the mould tool Cycle time - The moment it considers a mould cycle to be finished, i.

8 Simple Techniques For Plastic Injection Molding

from product feed & melting; product injection; cooling down time as well as ejection to the re-closing of the mould tool all set for the next cycle. Draft angles - The walls of a moulded component ought to be a little tapered in the direction in which the component is ejected from the mould device, to enable the component to be ejected conveniently.Ejector stroke - The pushing out of ejector pins to eject the moulded component from the mould device. Ejector stroke speed, length and also timing needs to be meticulously controlled to stop damage to the ejectors as well as mould tool, however at the exact same time make the moulding cycle as short as feasible.

The 5-Minute Rule for Plastic Injection Molding

Overlocking - When a mould tool has been set right into a moulding machine incorrectly, causing the tool to shut too hard therefore damaging the mould tool Part repeatability - The ability to develop the same plastic part-times after time Distance - Flawlessly straight edges are difficult to eject from the mould tool.Ribs - When a plastic part has slim wall surfaces, ribs are included in Your Domain Name the design to make the thin wall surfaces more powerful Side cores - Side activity which produces an attribute on a moulded part, at an opposing angle to the typical opening instructions of the mould tool. The side core requires to be able to withdraw as the plastic component can not be ejected otherwise.

Wall surfaces - The sides of a moulded component The text on this page is an example from our complete White Paper 'Injection Moulding for Buyers'.

Shot moulding is commonly made use of for producing have a peek here a selection of parts, from the tiniest components to entire body panels of cars. Shot moulding makes use of a special-purpose maker that has 3 parts: the shot device, the mould as well as the clamp.

Plastic Injection Molding Fundamentals Explained

In several cavity moulds, each tooth cavity can be identical as well as form the exact same parts or can be special and develop numerous different geometries throughout a single cycle.

When sufficient material has gathered, the material is forced at high pressure and speed into the component developing dental caries. The specific quantity of shrinkage is a function of the resin being utilized, as well as can be reasonably predictable. To stop spikes in stress, the process generally makes use of a transfer position corresponding to a 9598% full cavity where the screw shifts from a consistent velocity to a continuous stress control.

Once the screw gets to the transfer position the packing pressure is used, which finishes mould dental filling as well as makes up for thermal shrinkage, which is quite high for thermoplastics about several various other products. The packing pressure is used till eviction (dental caries entryway) solidifies. Due to its small dimension, eviction is typically the top place to strengthen with its entire thickness.: 16 Once eviction strengthens, no more material can get in the tooth cavity; appropriately, the screw reciprocates and gets product for the next cycle while the product within the mould cools down to ensure that it can be ejected and also be dimensionally steady.

Report this wiki page